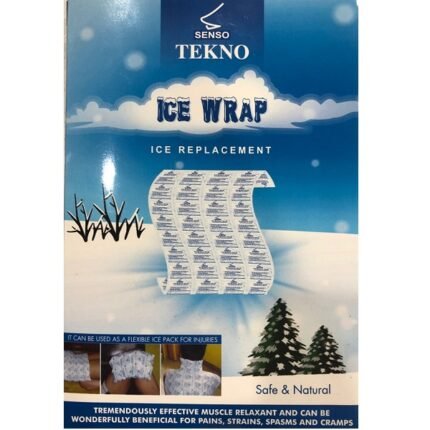

2 Ply Tekno ice Sheet

| Packaging Size | BOX OF 500 |

| Material | Polyster Nylon |

| Trademark | TEKNO-ICE |

| Product Type | Re-usable |

| Model Name/Number | TI -12 & TI – 24 |

| Brand | TeknoIce |

Description

Product Introduction

The yields of research and technology has arrived at TEKNO-ICE®– a revolutionary product taking packaging out of the Ice Age.

An effective alternative to conventional ice, TEKNO-ICE® is made from specially-treated non-woven fabric on one side and the other layer is an opaque Polyester polyethylene (P.P.E.) encapsulated between these two layers in a unique super-absorbent powder. Super absorbent powder selectively processed from acrylic resins for optimal water retention.

TEKNO-ICE® is finding ready acceptance in packing Pharmaceutical product, Veterinary products, Seafood, Fruit and Vegetable, Meat and Poultry, Flowers, Ice cream, Chocolates, Mushroom and Herbals etc.

When produced, TEKNO-ICE® is made in a square “cellular” form, and being grooved, it is intrinsically flexible so as to allow the product to be wrapped around the item being packed. Sold in an un-hydrated state, TEKNO-ICE® is lightweight and compact for ease of handling.

Once immersed in water, each TEKNO-ICE® “cell” will absorb a specific quantity of water and it will then be ready for freezing.

TEKNO-ICE® has 3 important attribute making it invaluable as an aid to temperature control in packaging – freeze factor, flexibility and fluid retention.

Freeze Factor

TEKNO-ICE® has excellent freeze duration capabilities when packed under proper conditions. Generally, you need pack less TEKNO-ICE® than wet ice and this means weight saving in the packaging process – pack more product / save on freight.

Flexibility

Because of its cellular construction, TEKNO-ICE® is inherently flexible – even when fully hydrated and frozen. The TEKNO-ICE® sheets can be folded or bent along the divisions between the sachet cells to match the shape of the product being packaged.

Fluid Retention

TEKNO-ICE® is formulated so that when it finally begins to thaw, it doesn’t release fluid into package, unlike wet ice. It holds the fluid within the structure, enabling full moisture control. When there is a need to conserve weight, stop fluid release, control temperature and prolong moisture retention, technology’s answer is TEKNO-ICE® .

How to use the Product

Preparation

To prepare TEKNO-ICE® pads, they should be immersed in water (Drinking Water) for east 15 to 30 minutes or even more to achieve maximum absorbency.

Once hydrated, the pads should be removed from the water and placed in a deep freezer for 10 to 12 hours. Individual pads should not be placed on top of each other during the freezing process but should be separated either by wire mesh or layers of flute board material.

Utilisation

In determining the required size of TEKNO-ICE® pads, packers will be further advised as each product size will produce different results depending on the product is being packed with.

The Basic Technology

The combination powder used in TEKNO-ICE® have the unique ability to absorb many times their own weight of water. On absorption of aqueous fluids the powder forms an expanded gel which continues to hold the absorbed fluids, thus preventing further contact of bio-fluids with the product. The fabric is a non-woven fabric polyester. It does not adhere to food products even after defrosting and was selected after considerable research because of its inherent properties which made it suitable for manufacturing as we as having superior strength and retention characteristics. It is the combination of powder and non-woven fabric that produced the technology of the TEKNO-ICE® Flexible Ice Sheets/ Pads.